How can industries ensure the longevity and effectiveness of their geomembrane systems? A geomembrane supplier plays a crucial role in providing high-quality materials, but proper maintenance is equally important to sustain long-term performance.

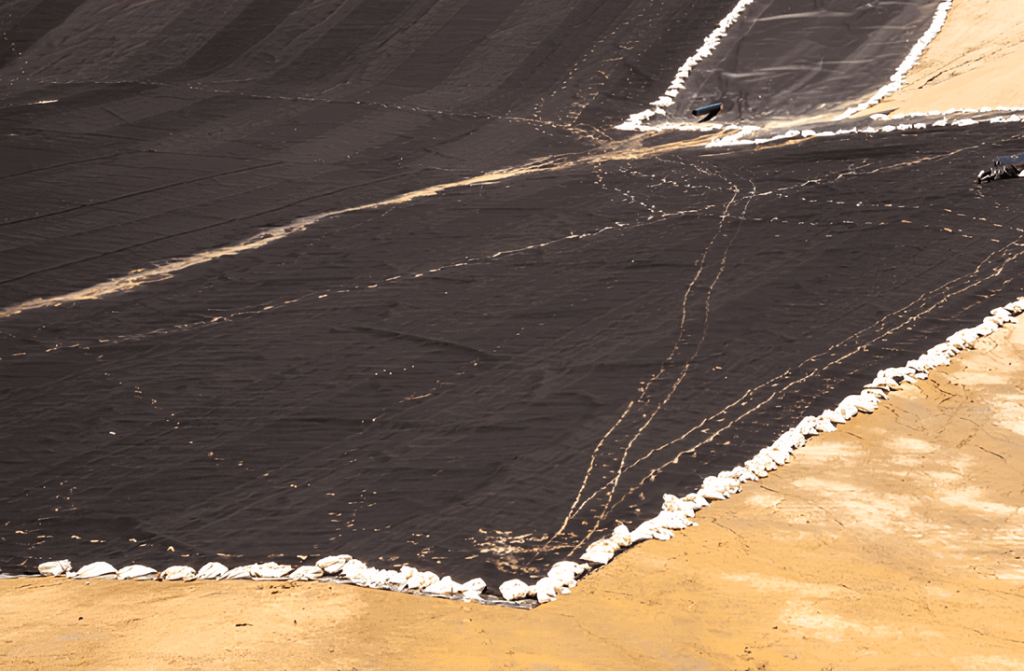

Geomembrane sheets are widely used in industries such as mining, agriculture, landfill containment, and water conservation to provide reliable environmental protection and containment solutions. These sheets act as barriers to prevent leaks, contamination, and soil erosion. However, to ensure their long-term performance and durability, regular maintenance and proper inspection are essential. Neglecting maintenance can lead to premature degradation, compromising the integrity of the entire system.

This article outlines the key aspects of geomembrane sheet maintenance, including degradation factors, inspection protocols, preventive measures, and the long-term cost benefits of proper upkeep.

Geomembranes are subjected to various environmental and operational stresses that can affect their performance over time. The primary factors contributing to geomembrane degradation include:

Understanding these degradation mechanisms allows for proactive maintenance to extend the service life of geomembrane systems.

Routine inspections are critical in detecting early signs of wear and damage, helping to prevent costly repairs or replacements. A comprehensive geomembrane inspection includes visual checks, seam integrity testing, leak detection, thickness assessment, and environmental impact evaluation.

Visual inspection involves regular site checks to identify cracks, punctures, deformations, or seam separations. Seam integrity testing ensures proper adhesion and bonding strength, often using non-destructive testing (NDT) methods such as vacuum box or air pressure testing. Leak detection systems, including electronic leak detection (ELD) or hydrostatic testing, help identify subsurface leaks and breaches.

Periodic thickness and flexibility assessments confirm the material remains within industry standards. Additionally, evaluating environmental factors such as water pooling, soil erosion, or chemical contamination ensures that external conditions do not compromise geomembrane effectiveness.

Scheduling regular inspections allows for early detection of issues, preventing larger failures in containment systems.

To minimize degradation and extend the operational life of geomembrane sheets, the following preventive maintenance strategies should be implemented:

A structured maintenance program helps maintain the integrity of geomembrane sheets and ensures continued operational efficiency.

Investing in proactive geomembrane maintenance provides several financial and operational advantages, including:

By implementing a consistent maintenance schedule, industries can maximize their investment in geomembrane technology while ensuring long-term sustainability.

Proper maintenance of geomembrane sheets is essential for ensuring long-term performance, structural integrity, and regulatory compliance. Regular inspections, preventive strategies, and early repairs can significantly extend the lifespan of these protective barriers while reducing overall operational costs.

By understanding the factors that contribute to degradation and implementing proactive maintenance measures, businesses and industries can maintain efficient, reliable, and environmentally responsible containment systems.

A well-maintained geomembrane system is not only a cost-effective investment but also a crucial component in sustainable environmental management.

Copyright © Gateway Structure Sdn Bhd (199401025111). All Right Reserved.