Airports demand exceptional standards in structural integrity, durability, and safety. From runways to taxiways, the base layers of these critical infrastructures must endure extreme loads from aircraft operations, all while resisting environmental degradation.

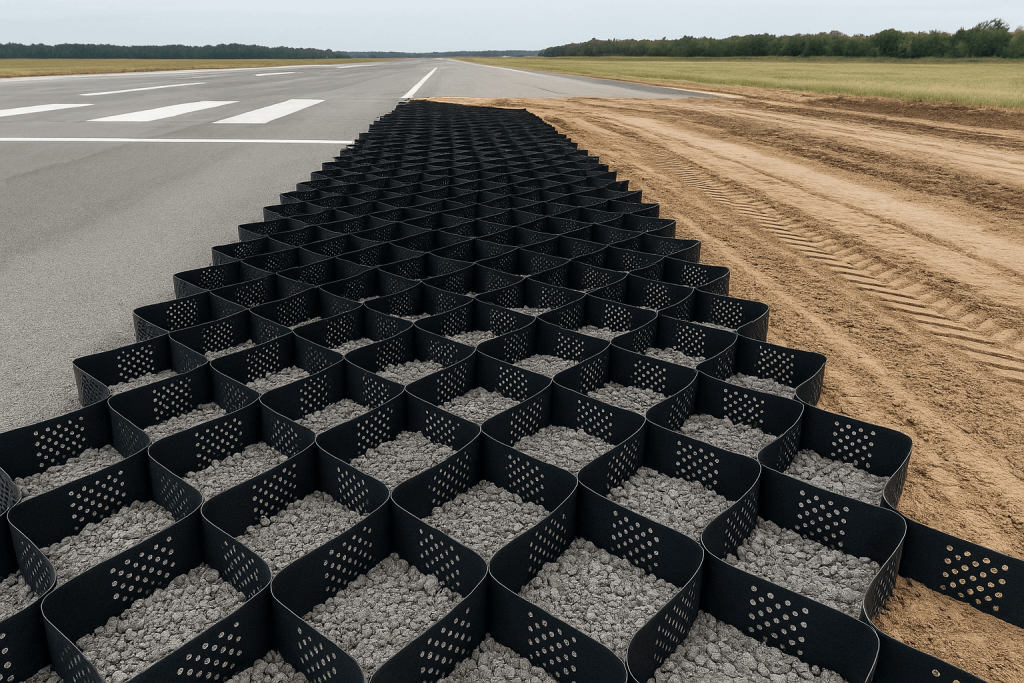

Among the most effective innovations for enhancing ground performance in such applications is the geocell—a three-dimensional geosynthetic solution that significantly improves soil stability and load distribution.

This article presents a comprehensive examination of how geocells, particularly HDPE geocell systems, reinforce airport runway and taxiway base layers, highlighting engineering advantages, use cases, and design considerations to support modern airfield construction.

Constructing and maintaining the structural base of airport runways and taxiways presents several complex challenges. These include intense dynamic loading from aircraft landings and take-offs, environmental cycles such as freeze-thaw conditions and water ingress, subgrade variability like weak or expansive soils, and stringent performance standards defined by international aviation authorities.

Traditional approaches—such as thick granular layers or reinforced concrete slabs—can be labor-intensive, time-consuming, and costly. Geocell systems offer a high-performance alternative that simplifies construction while enhancing structural performance.

When integrated into the base layers of runways and taxiways, geocell technology improves structural behavior by confining infill materials, which limits lateral movement and disperses vertical stress. It enables uniform load transfer and minimizes pressure on underlying subgrades. The increased modulus of the base layer enhances its load-bearing capacity, while reducing surface rutting even under repeated aircraft loads.

This reinforcement mechanism allows engineers to design thinner yet stronger base layers, significantly improving cost-efficiency and long-term performance.

One of the primary benefits of using geocells in airport infrastructure is enhanced load distribution. The honeycomb structure stabilizes infill materials, transforming granular bases into semi-rigid, load-supporting platforms that uniformly distribute stresses and reduce the risk of subgrade failure.

Additionally, geocell-reinforced systems allow for substantial reductions in aggregate layer thickness—by up to 50% in some cases—which results in lower excavation costs and faster installation timelines.

For locations with weak or marginal soils, HDPE geocells provide crucial stabilization by increasing the modulus of the subgrade and preventing settlement or displacement under heavy loads.

Another advantage is the ability to use locally sourced or recycled fill materials within the geocells, significantly reducing the need for high-quality imported aggregates and thereby lowering material costs and environmental impact.

HDPE geocells are also engineered to resist UV exposure, chemical degradation, and biological attack, ensuring long-term durability and reliability even in harsh airport conditions.

Geocells have been successfully deployed across a broad spectrum of airport applications. These include runway base layer reinforcement to enhance bearing capacity under paved surfaces; taxiway structural support to resist deformation from repetitive gear loading; and edge or shoulder stabilization to control erosion and prevent lateral base movement.

Additionally, geocells are used in aircraft apron support, maintaining surface integrity under static aircraft loads, and in temporary airstrip construction where rapid deployment of load-bearing surfaces is required in remote or military environments.

To maximize the performance of geocell systems in runway and taxiway construction, several engineering considerations must be addressed. These include evaluating aircraft load profiles and operational frequency, subgrade characteristics such as moisture content and CBR values, and geocell dimensions including height, width, and wall thickness.

Engineers must also consider the properties of infill materials—whether standard aggregate or cement-treated base—alongside effective drainage strategies to prevent water accumulation. Compliance with international aviation guidelines such as ICAO and FAA standards is essential for successful implementation.

As airports continue to evolve to accommodate increasing aircraft traffic and stricter construction timelines, geosynthetic technologies offer forward-thinking solutions. The use of geocells, particularly HDPE geocell systems, in runway and taxiway base layers delivers measurable advantages—from enhanced performance and material savings to accelerated project completion and long-term sustainability.

For civil engineers, contractors, and airport authorities focused on efficiency, resilience, and cost-effectiveness, geocell systems provide a smart and strategic alternative to traditional base reinforcement methods.

Copyright © Gateway Structure Sdn Bhd (199401025111). All Right Reserved.